| Sign In | Join Free | My chinaqualitycrafts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinaqualitycrafts.com |

|

Brand Name : LIJIANG GLASS

Model Number : LJZW2020A

Certification : CE

Place of Origin : CHINA

MOQ : 1 set

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 50 sets per month

Delivery Time : 60 days

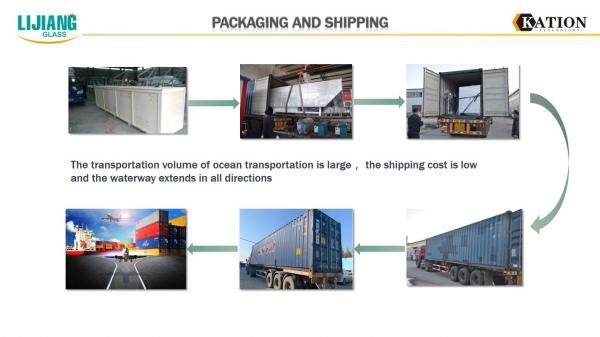

Packaging Details : Container

Production name : Automatic Insulating glass aluminum alu-spacer bending machine

Max spacer size : 1800mm*2000mm

Min.bending machine : 150*250mm

Spacer types : Aluminum space/warm edge spacer

Servo motor : servo motor

Machine type : Beading Machine,

Usage : aluminum spacer bar bending, bend aluminum spacer bar into required shape

Automation : Automatic

Aluminum spacer width : 5.5-26.5mm

Automatic Insulating Glass Aluminum Spacer Bending Machine for glass Processing

Automatic Insulating Glass Aluminum Spacer Bending Machine for glass Processing

Technical parameter of Automatic spacer frame bending machine

| Max. bending size

| 2000mm*2000mm |

| Min. bending size

| 250mm*180mm |

| Aluminum spacer width

| 6A - 27A |

| Spacers racks | 4 Racks |

| Spacer size error

| ±0.5mm |

| Angle error

| ±1° |

| Processing speed

| < 25s (1000mm*1000mm) |

| Air supply

| ≥0.65MPa |

| Voltage | 380V50Hz 3P |

| Total power | 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Main feature of Automatic Aluminum Spacer Bending Machine

●LIJIANG GLASS Aluminum spacer bending machine adopt the servo control feeding system, spacer frame size can be adjusted with an accuracy of 0.1 mm/m

●Aluminum bar with multiple sizes can be selected at will

Automatically adjust the bending speed according to the size of the aluminum frame

to avoid the deformation of the large frame and ensure the high speed and continuity of the small frame

●Set up four groups of spacers storage units

●Automatic continuous connection of spacer, cutting spacer,avoldance of spacer bar joint

●No material prompt, sleep prompt, fault prompt, work prompt,unreasonable data

refuse processing and prompt Support arc-shaped aluminum frame and special. shaped aluminum frame bending

● USB function, which can read excel directly● Connect with ERP (optional)

Production Overview of aluminum alu-spacer bending machine

AInsulating glass is made by 2pcs or more float glasses which filled with desiccant of Argon gas with Aluminum frame.Primary seal(butyl)between insulating glass and Aliminum frame, secondry seal(polysulfide or structure). Insulating glass will be effectively protect radiation when coated Low-E film.

Automatic Aluminum spacer bending machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology.

Automatic Spacer bending machine can make a variety of convex polygonal aluminum frames by one aluminum strip in one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass more better.

Detail of Automatic spacer bending machine

1.German siemens plc control system,touch screen interface.

Siemens 1200PLC control system with fast working speed.

2.Automatic Aluminum spacer bending machine have Four or Twelve different spacer size storage units can choose

3 Aluminum spacer bending machine can automaticlly cut and feed Aluminum spacers

4.Heavy duty connectors ,convenience and safety for installation and debugging

5. Aluminum spacers are available in different specifications and in sizes of 6A-27A.

6.Spare parts of all machine have ID codes.

7.Support continuous bending , it automatically avoid spacer -connection while bending and cutting

8.Precise bending effect, corner error less than 0.1mm.

9.The special machine hand device is used to bend big spacer frame

10.Automatic spacer bending machine can bend aluminum spacer /technoform /Alupro /swisspacer/ stainless steel /thermix (optional)

11.Printing paper label sticker function (Optional),could remove it easily.

11.USB input function ,it can read the excel data directly

Related Product

Sealant-spreading Machine LJST02A

Main feature

• Imported motor system to improve equipment efficiency

• Imported sealant gun,stainless steel mixer

• High pressure protect device

• Anti-back flow control structure

• Mixed rate detector can control the rate of two kinds of glue

Technical data

| Working air pressure | 0.3-0.6MPa |

| Sealant spreading pressure | 15-20MPa |

| Sealant volume | 4L/min |

| Diameter of A/B sealant | 570mm/280mm |

| Sealant spreading air pressure ratio | 50:1 |

| Mixed rate | 6:1-14:1 |

| Air supply | Flow 0.8m3/min |

| Air pressure | ≥0.8MPa |

| Overall dimension | 1100*950*1630mm |

Butyl Extruder Machine LJTB 01

Main feature

• PLC control system, touch screen interface

• Automatically identify the width of aluminum bar, the glue nuzzle can be automatic adjust

• The critical part of the hydraulic system using German imports of components to ensure that the plastic evenly full

• Fast preheat, improve work efficiency

• with preheating function

• With exhaust inflatable function, improve the quality of sealing and save time for plastic

• Quickly coating speed,can up to 47m/min

• Saving the amount of glue

Technical data

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Aluminum spacer width | 6A - 27A |

| Speed | 5-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 650kg |

Electrical parameters

| Name | Original | Brand |

| PLC | China | KINCO |

| Valve | German | HAWE |

| Low voltage electrical apparatus | German | SIEMENS |

| Hydraulic and pneumatic supercharging system | German | MAXIMATOR |

| Frequency converter | China | KINCO |

| Pneumatic components | Taiwan | ARTAC |

| Quick exhaust valve/Vacuum generator | Japan SMC | SMC |

| Travel light | Japan | OMRON |

| Optical fiber | Japan | OMRON |

Smart Vertical Edge Deleting Machine LJCM2545

Main feature

• Two-way glass access

• Automatically measure size

• Automatically distinguish low-e surface

• The head can be rotated 360°

• Safe and full automatic device

• PLC control system, touch screen interface

• Six servos control system

• Edge deletion is adjustable

• Intelligent control system, can recognize batch processing

Technical data

| Max. glass processing size | 2500*4500mm |

| Min. glass processing size | 400*280mm |

| Glass thickness | 3-15mm |

| Diameter of grinding wheel | 200mm |

| Conveyor height | 500mm |

| Edge deleting width | 10-50mm |

| Transmission speed | 1. 29m/min |

| Edge deleting speed | 2-29m/min |

| Abrasive wheel width | 10/12/15mm |

| Glass thickness | 3 - 15mm |

| Grinding wheel speed | 0~3000r/min |

| Total air consumption | 100L/ min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50Hz 3.35KW |

| Dimension | Dimensions :9700×2500×3400mm |

| Total weight | 3700KG |

Electrical parameters

| NAME | ORIGIN | BRAND |

| Servo motor | Taiwan | TAIDA |

| PLC | Taiwan | TAIDA |

| Pneumatic component | Taiwan | AAIRTAC |

| Low pressure electricity | Germany | SIEMENS |

| Circuit breaker | Germany | SIEMENS |

| Sensor switch | Korea | AUTONICS |

| Approach switch | Korea | AUTONICS |

| Limit switch | Taiwan | TEND |

| Connector | Germany | SIEMENS |

| Frequency converter | France | SCHNEIDER |

| Main Button | France | SCHNEIDER |

| Intermediate relay | Japan | OMRON |

Butyl Extruder Machine LJTB 03

Main feature

• PLC control system, touch screen interface

• Frequency control system

• Arc frame coating structure

• Imported pneumatic and hydraulic supercharging system

• Automatic centering and clamping structure

• Loading capacity up to 14KG, saving time for feeding glue

• Adopt five steps to control convey

• Preheating function,glue cylinder limit function,alarm system

• Covey and gluing mechanism adopts the latest design

Technical data

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Aluminum spacer width | 6A-27A |

| Speed | 0-40m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5KW,50HZ |

| Dimension | 2600×680×1100mm(L×W×H) |

| weight | 650kg |

Glass Washing Machine

Main feature:

• Using 6 pieces of soft brushes

• Wash online and offline low-e glass, automatically recognizes Low-e film

• Washing part adopts the design of upper and lower layered structure

• Adopt variable frequency fan, energy efficient, good cleaning effect

• The air knife can automatically adjust the width of the air knife according to the thickness

• Using intelligent intermittent energy-saving working methods

• Hierarchical type washing system

• Water tank automatic temperature control, water replenishing system

• European silencer system

• 304 stainless steel materials

3.Desiccant Filling Machine

Main feature

• Adopt Siemens PLC control system

• Touch screen interface, easy operation

• The height can be adjusted according to the size of spacer frame

• Automatically loading and replenish desiccant

• Filling time can be adjusted

• Automatically drilling, filling and sealing

• Core parts are imported brands

• Arc frame (optional)

• Fill large particle molecular sieve (Optional)

Technical data

| Max. frame size | 2000mm*2000mm (2500mm*2500mm) |

| Min. frame size | 300mm*250mm |

| Aluminum specifications | 6A- 27A |

| Air source | ≥0.65MPa |

| Power supply and power consumption | AC220V 50Hz 1KW |

| Molecular sieve diameter needed | 0.5-0.8mm |

| Dimension | 1100mm*1100mm*3600mm |

|

|

Glass Processing Spacer Bending Machine Aluminum Spacer / Warm Edge Spacer Images |